New product: Suspended backlash measurement machine

Jendamark India has designed and developed a new suspended backlash measuring machine for our axle assembly customers using trolley-based systems instead of conveyor lines. Measuring the amount of backlash is important to reduce power transmission losses in the gear...

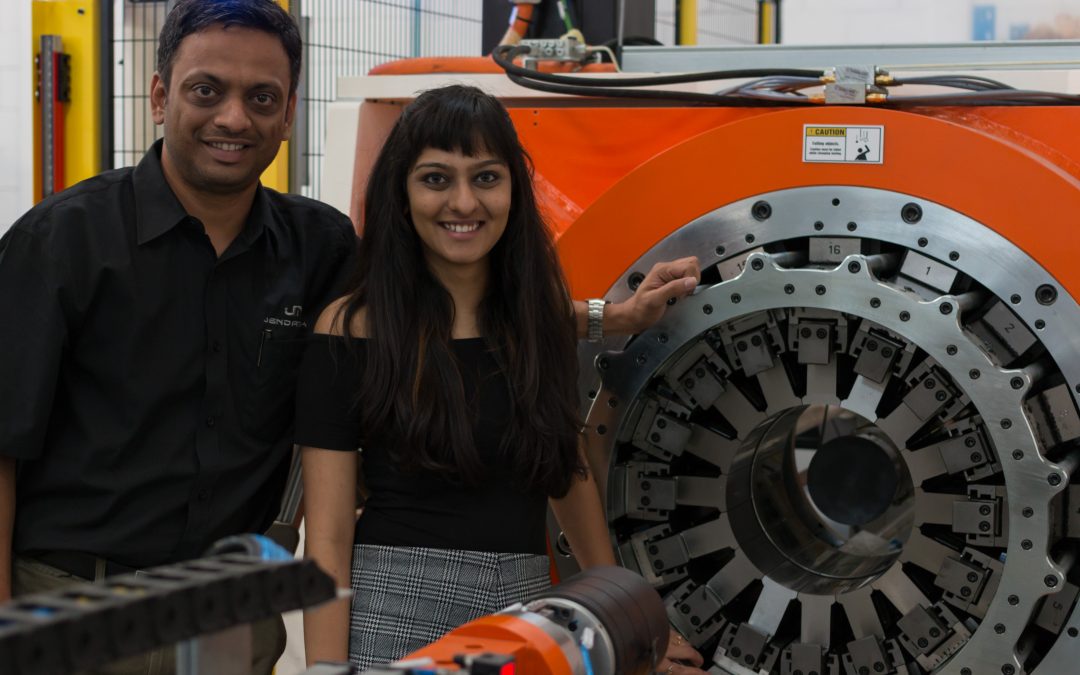

Driving an electrifying pace

With the Indian government offering attractive incentives to electric vehicle (EV) buyers, Jendamark India is rapidly becoming a trailblazing player in the country’s quest for cleaner energy.

Building the future

Determined to create a more conducive environment for learning, Jendamark India recently partnered with the new Zilla Parishade (District Council) School in Velu to fund the building of a classroom. This newly built, government-run school serves 300 pupils, whose...

Pioneering the change

With the BS-VI (Euro 6) emission standards deadline of April 2020 looming, Jendamark India has been hard at work, rolling out its first adaptive canning lines for customers. SHARDA MOTOR INDUSTRIES Sharda Motors was the first customer, ordering two identical canning...

India can do it

Part and parcel of Jendamark India’s programme to help the automotive industry achieve the desired Bharat Stage 6 emission norms are canning lines for Tier 1 suppliers like Sharda Motors, Faurecia, Cummins and Tenneco.

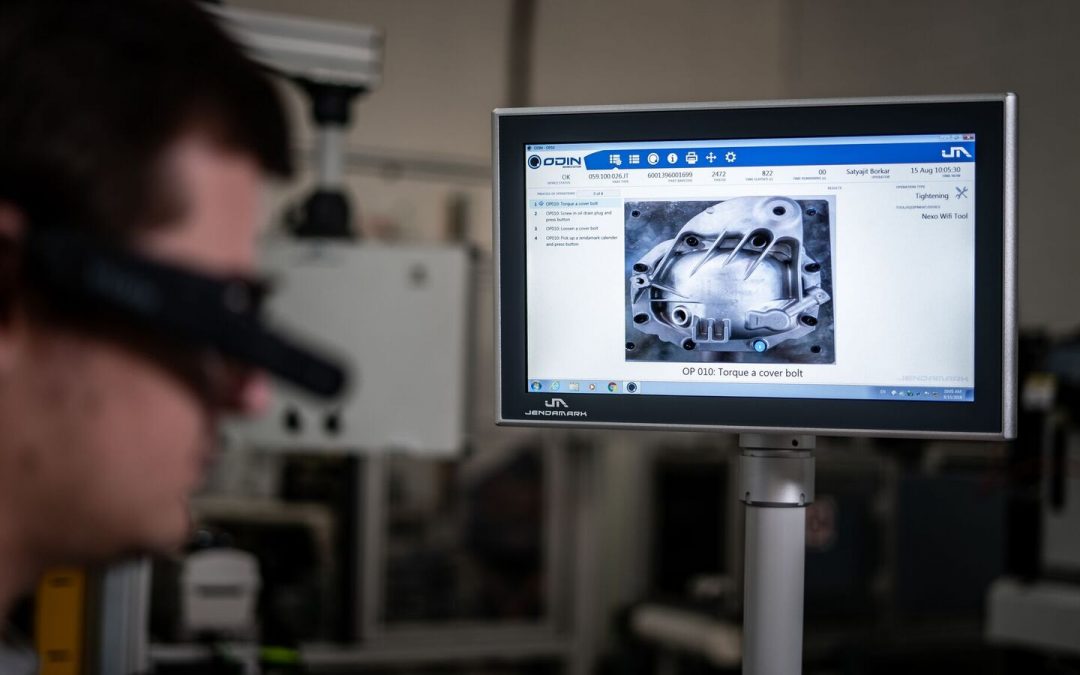

Tech power

In 2018, Jendamark Techcellency (JMKT) delivered a first for India and its biggest order to date – an innovative engine assembly line that uses augmented reality to guide its operators.

Industry 4.0: Virtual reality

Jendamark’s virtual reality room allows designers and customers to explore the possibilities of a new production line in three-dimensional reality via an interactive, computergenerated experience. The introduction of virtual reality (VR) has had tangible, real world...

Industry 4.0: Internet of Things

The Internet of Things (IoT) describes a network of machines, devices and other items that have built-in connectivity, electronics, software or sensors that allow them to share data and improve efficiency for humans interacting with them. While the idea of a “smart...

Industry 4.0: Augmented reality

Augmented reality (AR), as the name suggests, uses technology to augment or add to a user’s experience by superimposing computer-generated images, text and sounds over a real-world environment. AR creates an immersive and interactive experience for the user, which...

Industry 4.0: Predictive maintenance

Adding a predictive maintenance element to an already efficient automotive assembly line can add unnecessary costs. Jendamark has found a better way to predict machine downtime, which will soon be added as the fourth module to its Odin software platform. “Typically, a...